Many in the construction industry know that the construction industry has to embrace the changes that should have taken place in the past. Materials and technologies are constantly developing, and those who work in the field must be up-to-date with the latest trends to stay relevant. As we enter 2024, construction continues to change due to various factors affecting how the construction process is planned, carried out, and completed. Every day brings new developments demonstrating the company’s commitment to sustainability, technological advancement, safety standards, and ability to adapt to market volatility. Specific major trends have already started showing the pledges made to sustainability: sustainability and technological advancement, safety elements, and the ability to adjust.

Adopting cutting-edge materials such as carbon fibre-reinforced polymers or 3D-printed construction materials opens up new possibilities for eco-friendly and efficient construction projects. These include excellent durability, lower environmental impacts, and higher energy efficiency. These modern construction materials have improved durability and energy savings that can help improve cost efficiency and ecological sustainability.

In addition to technological advancements, work automation, and artificial intelligence have revolutionized the construction industry. Robotic systems can now perform repetitive tasks, such as concrete pouring or bricklaying, with precision and speed; Artificial Intelligence software analyzes large quantities of data to improve construction timetables, spot risks earlier, and improve decision-making ability.

What Is Construction Technology?

Construction technology refers to the latest technology and solutions used in the construction industry to improve productivity and safety in the workplace, improve sustainability, and adopt more efficient methods.

These tools and applications do not aim to replace experienced construction professionals; instead, they are designed to reduce particular of the most challenging and hazardous aspects of building work. Today’s construction industry has various tools, applications, software, and programs that help it plan, create, build, or oversee projects.

Want to know the exact cost estimation and expected returns for using drone technology in your construction business?

Pooja Upadhyay

Director Of People Operations & Client Relations

Construction technology has revolutionized construction by bringing equipment, tools, and software programs to complement their capabilities. It has also simplified the pre-construction process. Implementing tools such as bid management, document organizing tools, and collaborative platforms allows contractors and construction teams to level the playing field in every phase of a construction project.

Mobile apps that aid in project management, innovative equipment and tools, digital schematics, automated machinery, and 3D printing technology that can prefabricate cost-effective but top-quality building materials are just a few of the numerous technological innovations changing construction today.

What Are the Advantages of Construction Technology?

From 2004 to now, technology firms and construction companies have invested around $10 billion in custom supply chain software development. These technologies have revolutionized how workers perform their tasks at construction sites.

Improve Safety:

Construction technology can improve security on the job site. Construction managers can review safety information to enhance procedures on site; some companies are now using drones to look over potential danger areas that could cause harm to humans. Other companies use wearable technology such as carbon monoxide detectors, motion sensors, and temperature monitoring to track the conditions; solutions such as robotic layout automate the repetitive and risky design elements for construction and decrease the risk of accidents on construction sites.

Increased Efficiency

Construction technology streamlines processes and cuts down construction schedules to speed up the process, such as more efficient 3D printing of building elements. At the same time, other methods, like robotic layout printers, can directly print digital models of buildings on construction site surfaces, allowing for precise installations and layout without rework—thereby saving time and resources.

Better Quality

The latest technologies, such as Augmented Reality (AR), can deliver real-world directions directly onto the worksite, allowing workers to accomplish complex tasks with greater precision than they did before. Additionally, robotic layout printers print the coordinated digital model directly onto surfaces within 1/16″, ensuring the highest quality and accuracy at work. These technologies minimize the risk of errors while improving the quality of construction projects.

Compliance Adherence

Tools like document management, storage of photos and videos, and real-time notification help construction workers comply by recording and delivering documents directly to regulatory agencies. Construction teams can use these technologies to abide by the rules and laws applicable to their business and projects.

Improved Collaboration:

Using Cloud-based Project Management Software, team managers and manager members can simultaneously view updates, messages, and much more via the user-friendly dashboards of project management. Construction professionals in the field stay up-to-date with the latest developments in construction through fully automated robot layout printing based on coordinated models that print all different trades’ plans, enhancing collaboration while reducing cross-trade conflicts.

Cost Savings

Construction technology can help construction companies and clients reduce the waste they produce while optimizing their resources, resulting in cost savings that directly translate into lower costs for both parties involved in projects. For instance, 26% of the construction executives said they had increased their utilization of modular and prefabricated materials because of construction technology. In their organizations, expenses decreased by 6 to 30%!

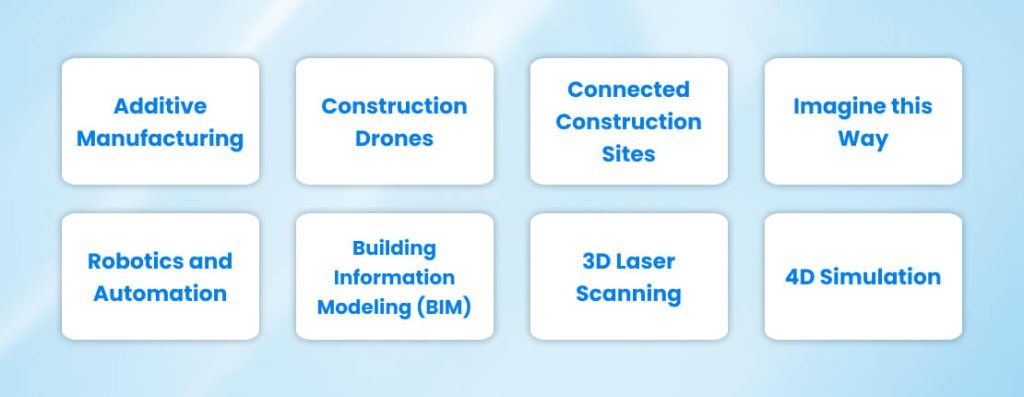

8 Emerging Construction Technologies of 2024

While inflation is responsible for an apparent increase in productivity, the natural world was characterized by increased expenditure due to the rising cost of commodities and a soaring labor cost, which increased the risks associated with construction projects. The construction industry had to confront these challenges head-on in the face of the rising cost of basic materials like wood and steel while also incurring high labor costs and financial issues, which increased the risks associated with their projects exponentially.

While experts predict that construction materials prices will be stable by 2024, many of the challenges that contractors face could remain problematic in the coming year. More money may be devoted to manufacturing or massive construction projects, such as roads and bridges, which will boost the demand for software development for the construction industry.

Additive Manufacturing

3D printing is an exciting new approach to construction. Instead of using bricks and mortar techniques, builders can now “print” large objects, such as bridges, building components, and skyscrapers, using specially designed machines that act as 3D printers based on computer files, speeding up the time to complete projects while saving the cost of labor while encouraging the use of more sustainable wood and metal for construction projects.

This innovative method of construction could dramatically speed up the time to complete projects while also saving on the cost of labor. If utilized carefully, it could help speed up the time to complete projects and reduce the cost of labor while being more conscious of construction materials like wood and metal than ever before!

Construction Drones

Drones used in construction act as cameras in the air, permitting construction workers to see details that would otherwise be difficult to view from a distance—such as damage to the structure or fissures within structures. Drones with laser sensors could also inspect any location before work can begin on it.

In 2024, contractors will employ drones and virtual reality technologies to obtain exact measurements of the size and appearance of future buildings. This will help maintain the highest quality standards in building projects while assisting technical engineers and project managers in performing their jobs quicker and more effectively.

Connected Construction Sites

The term “connected construction site” refers to any network that is extensive enough to include every piece of equipment, vehicle, device, and employee on a construction site. This network is connected via wireless or digital technology and managed by one company or organization.

Imagine this Way

Imagine a web where people, places, and tools are connected to improve collaboration, share information faster, and be more seamless as a team.

Imagine a work environment where IT teams centrally manage and interconnect every computer and device. Add construction vehicles such as bulldozers or cranes to this network, which all control and communicate with each other in a single system. That’s how construction is connected—similar to having smart offices on construction sites!

Robotics and Automation

Construction is one of many other industries embracing robots and automation technologies to simplify business processes. Robots provide many advantages that help overcome staff shortages, cut costs, and ensure sustainability—not overworking or making costly mistakes that require rework and working faster to speed up the project implementation.

Building Information Modeling (BIM)

BIM permits builders, designers, and operators to effectively build and manage data during project planning, building, and operations phases. BIM integrates data from different software programs into precise digital models, which are then worked on in open clouds, allowing real-time collaboration that gives greater visibility, better capacity for decision-making, and cost savings initiatives in the construction of architecture (AEC) construction projects.

3D Laser Scanning

A 3D laser scanner emits brief pulses of light that bounce off surfaces before returning to the source. Using LiDAR technology, the scanner calculates the distance by timing how long the light returns, making each data pulse into points with specific coordinates.

To cover an entire area precisely, the laser must be used from various places across the area to examine specific objects at various levels and distances. After collecting the data, millions of points will be merged into an exact 3D model of what it looks like.

Autodesk believes that laser scanner technology is new. Its initial widespread use only began in the 1990s. Autodesk believes that the use of laser scanning technology will rise exponentially in the construction sector by 2024 and anticipates a potential $10 billion increase in this sector alone.

4D Simulation

The goal of using 4D simulation is to include an element of time in a 3D model of a building in 4D, similar to creating a calendar for the year that displays when each phase is completed, with complete visualizations of the various construction processes involved in completing it.

Project participants, including builders and architects, will use this tool to envision how a building can be put together piecemeal. Although 4D simulation was used before BIM was used in conjunction with planning, their combination allows for greater efficiency in monitoring during different stages.

Conclusion

The construction industry constantly changes, so firms must keep up with the latest advancements in software development. From cutting-edge BIM solutions and extensive data analytics services to digital transformation services, techniques and tools are available to boost project efficiency, reduce risks, and ensure long-term success for any construction company. Using emerging technologies, construction companies can establish themselves as market leaders and better meet client needs than their competitors.

Innovations in the construction industry, including 3D printing, drones for construction, modular construction, and BIM, will lead the industry into a new digital future.

These solutions offer tremendous benefits: quicker, less expensive, more secure, and safer construction projects. The first to adopt these technologies quickly will gain an advantage in the market due to their improved efficiency and more efficient projects.

Enter the new age of construction technology with AddWeb Solution Artificial Intelligence development services.

Pooja Upadhyay

Director Of People Operations & Client Relations